From military to space and from medical to electrical industries, everywhere cable connectors play an important role in connecting different circuit boards. They have multiple uses and the basis of electricity generation through the wire. They have some complex features and here I will explain a little about how they work. Most custom connectors have male and female parts where the male parts have pins projecting outward and the female parts have sockets that are recessed below the insulator surface!

Both the parts are “polarized” so that they do not “mate” in a disoriented manner. This is extremely essential for their joining otherwise no electric signal will flow through the circuit. They are used for many consumer electronics. The Custom cable assemblies as the name suggests are integrated in a manner that the specific requirements of a user are fulfilled. The added advantage is that custom connectors come in various shapes and sizes to fit your needs. It not like a ‘one size fits all’ theory! The exact print requirements of a user is analyzed and then the work on actual design and manufacturing is started.

AdamTech is a company that uses the latest technology and very careful analysis of your requirements before jumping off with the manufacturing work. All its products are environment friendly and it makes sure not to release hazardous materials into the air in the manufacturing process. Ideally you should choose such a company and it also delivers high quality cable design engineering, drawing and sampling reports.

How waterproof connectors are helpful?

Now connectors can easily catch dust and moisture. The small amount of moisture may get accumulated over time and cause erosion of wire and faulty behaviour in their operations. To avoid some harsh weather conditions like rain/storm and to generally enhance the life-span of the cable, waterproof connectors are used. An IP67 waterproof connector provides resistance against sand, dust, salt spray, UV radiation and temperatures up to 200 degree celsius. The term IP means ‘Ingress Protection’ and these types of cable connectors also provides protection against any liquid ingress. Adam Tech is a huge warehouse, manufacturing all types of waterproof connectors which align with IP67 specifications.

Because of their ability, the waterproof connectors are mostly used in high intensity industries like industrial machinery, test and measurement industries and many industries that use high amount of heat and pressure.

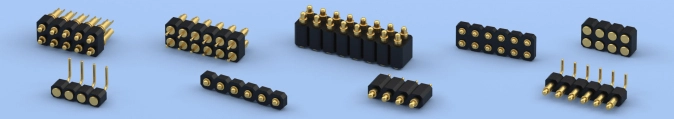

Pogo pins for small electronic devices

While waterproof connectors solve most problems, pogo pins are used in cases where small electronic devices needs connectors between printed circuit boards. They are small sharp pins that make secure contact between two circuits and enhance the flow of electricity. They are used in mobile phones, automotive, medical devices, aerospace and much more.

Thus, after knowing these types of connectors and their usages, you would be able to take a wise decision of which type of connector does your industry needs.

Both the parts are “polarized” so that they do not “mate” in a disoriented manner. This is extremely essential for their joining otherwise no electric signal will flow through the circuit. They are used for many consumer electronics. The Custom cable assemblies as the name suggests are integrated in a manner that the specific requirements of a user are fulfilled. The added advantage is that custom connectors come in various shapes and sizes to fit your needs. It not like a ‘one size fits all’ theory! The exact print requirements of a user is analyzed and then the work on actual design and manufacturing is started.

AdamTech is a company that uses the latest technology and very careful analysis of your requirements before jumping off with the manufacturing work. All its products are environment friendly and it makes sure not to release hazardous materials into the air in the manufacturing process. Ideally you should choose such a company and it also delivers high quality cable design engineering, drawing and sampling reports.

How waterproof connectors are helpful?

Now connectors can easily catch dust and moisture. The small amount of moisture may get accumulated over time and cause erosion of wire and faulty behaviour in their operations. To avoid some harsh weather conditions like rain/storm and to generally enhance the life-span of the cable, waterproof connectors are used. An IP67 waterproof connector provides resistance against sand, dust, salt spray, UV radiation and temperatures up to 200 degree celsius. The term IP means ‘Ingress Protection’ and these types of cable connectors also provides protection against any liquid ingress. Adam Tech is a huge warehouse, manufacturing all types of waterproof connectors which align with IP67 specifications.

Because of their ability, the waterproof connectors are mostly used in high intensity industries like industrial machinery, test and measurement industries and many industries that use high amount of heat and pressure.

Pogo pins for small electronic devices

While waterproof connectors solve most problems, pogo pins are used in cases where small electronic devices needs connectors between printed circuit boards. They are small sharp pins that make secure contact between two circuits and enhance the flow of electricity. They are used in mobile phones, automotive, medical devices, aerospace and much more.

Thus, after knowing these types of connectors and their usages, you would be able to take a wise decision of which type of connector does your industry needs.